- Products

- PREMIUM Acoustic panel 2440 mm

- PROFF Acoustic panel 3000 mm

- Acoustic panels 520 mm

- UNIKA Acoustic panel 2440 mm

- LIGHT Acoustic Acoustic panel 2500 mm

- Quanti Acoustic Panels 2440mm

- STONE Acoustic panel 2440 mm

- FibroTech FireGuard Panel

- Completion List: UNIKA

- Completion List: PREMIUM, PROFF, SQUARE

- Barcode Acousstic panels

- Wood-wool Cement Hexagon Box

- Calculator

- Storage/installation

- Prices

- Magazine

- Prices

- Samples

- Sustainable construction

- Contact

- Downloads

- Turkey

- Conditions

- Projects

- Cases

- Certificates

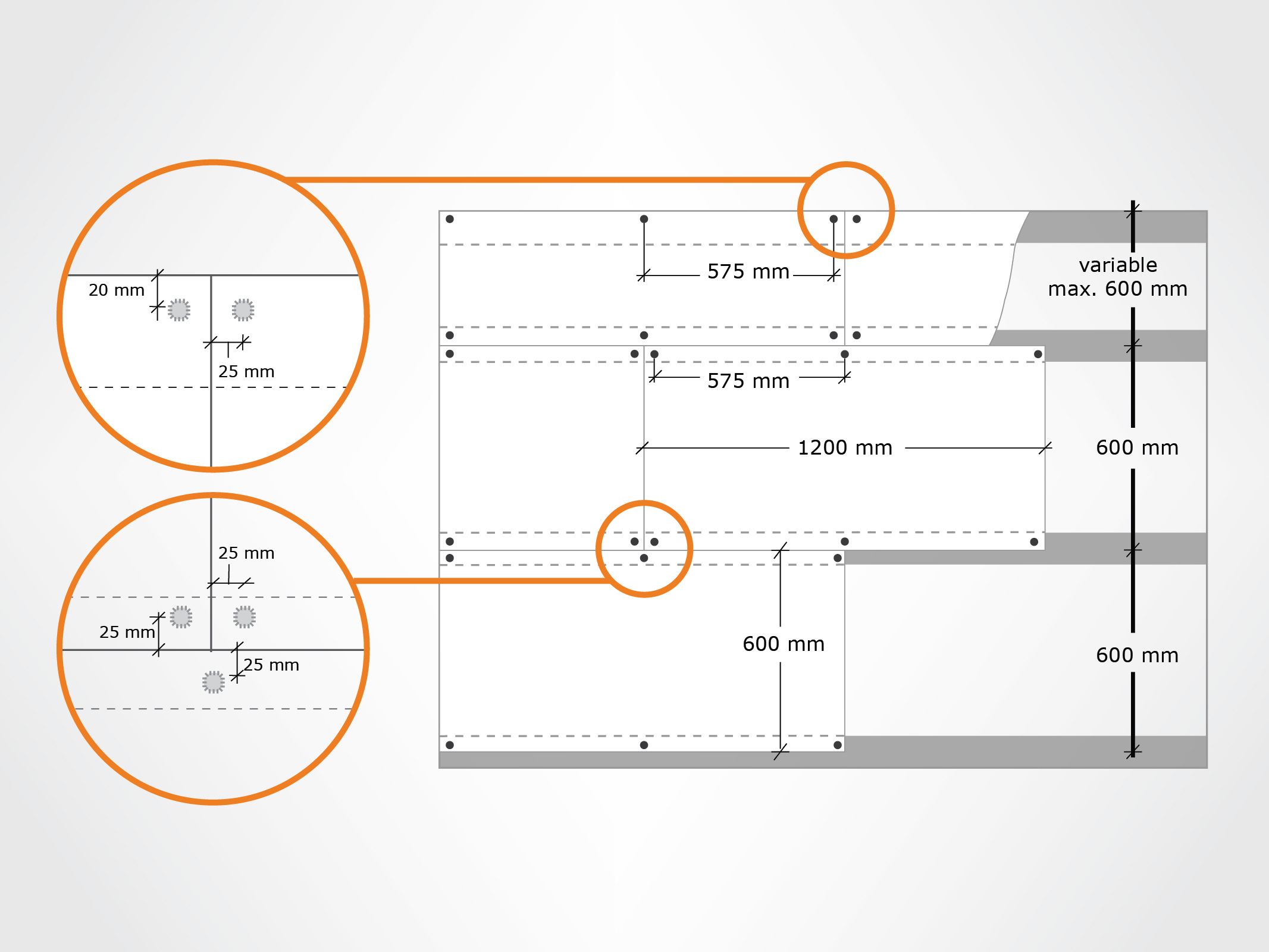

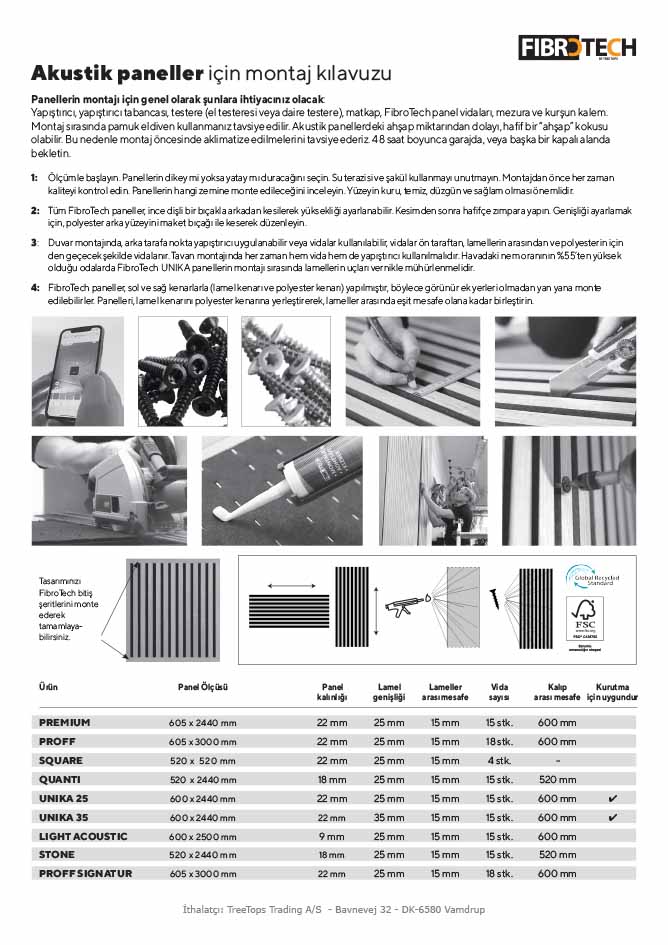

How to install FibroTech acoustic panels correctly

Wood-wool cement installation

Barcode installation

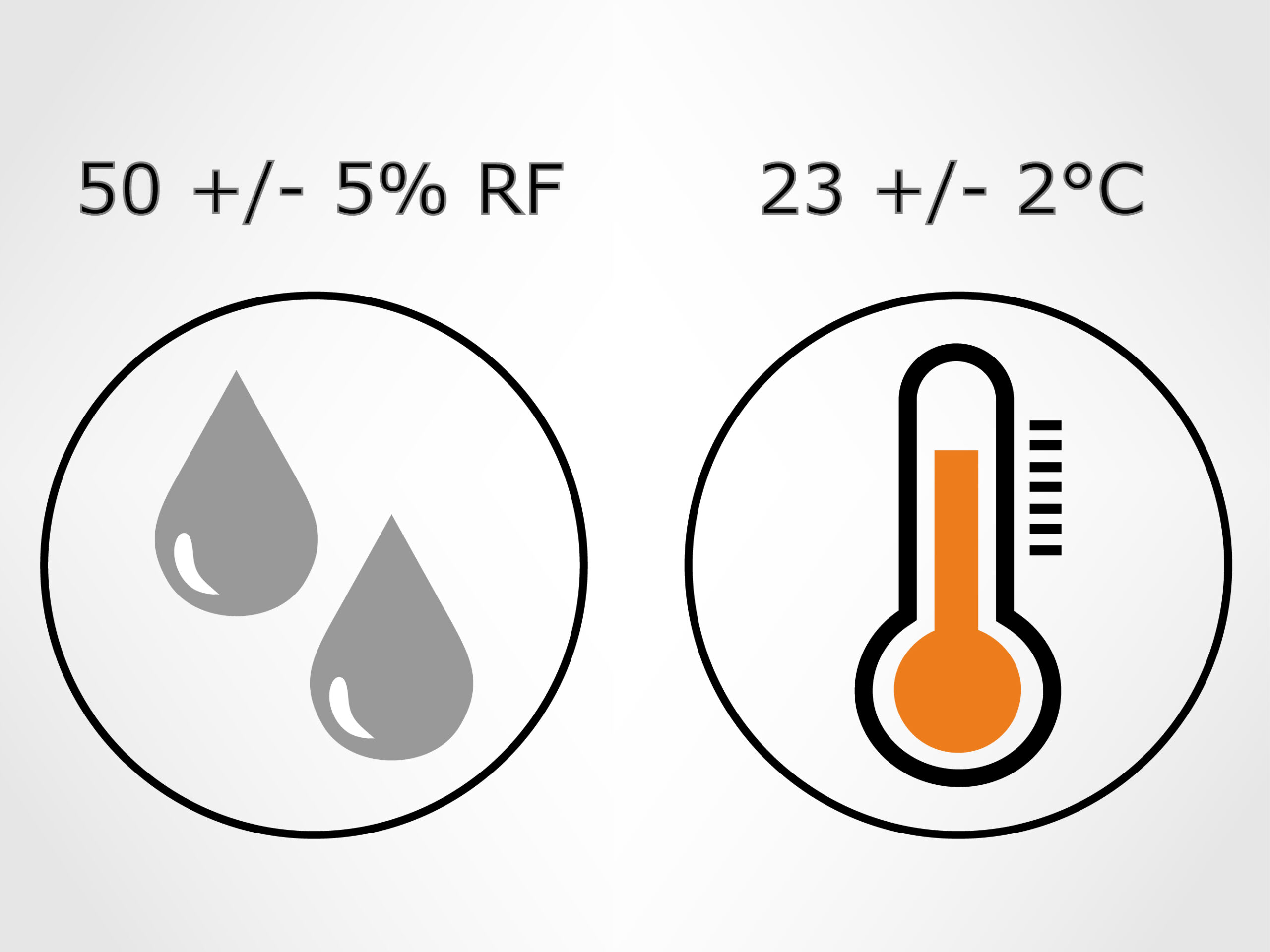

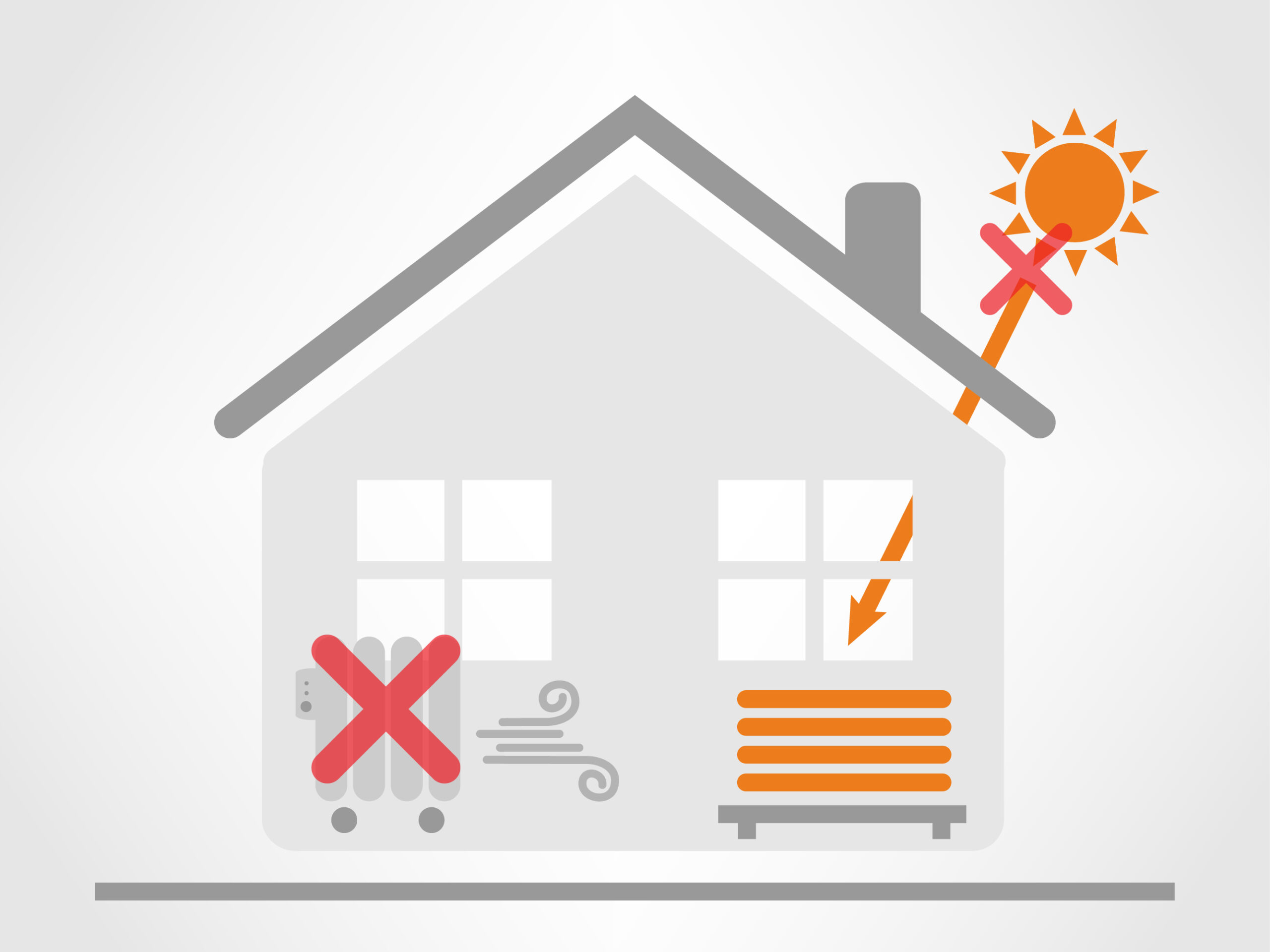

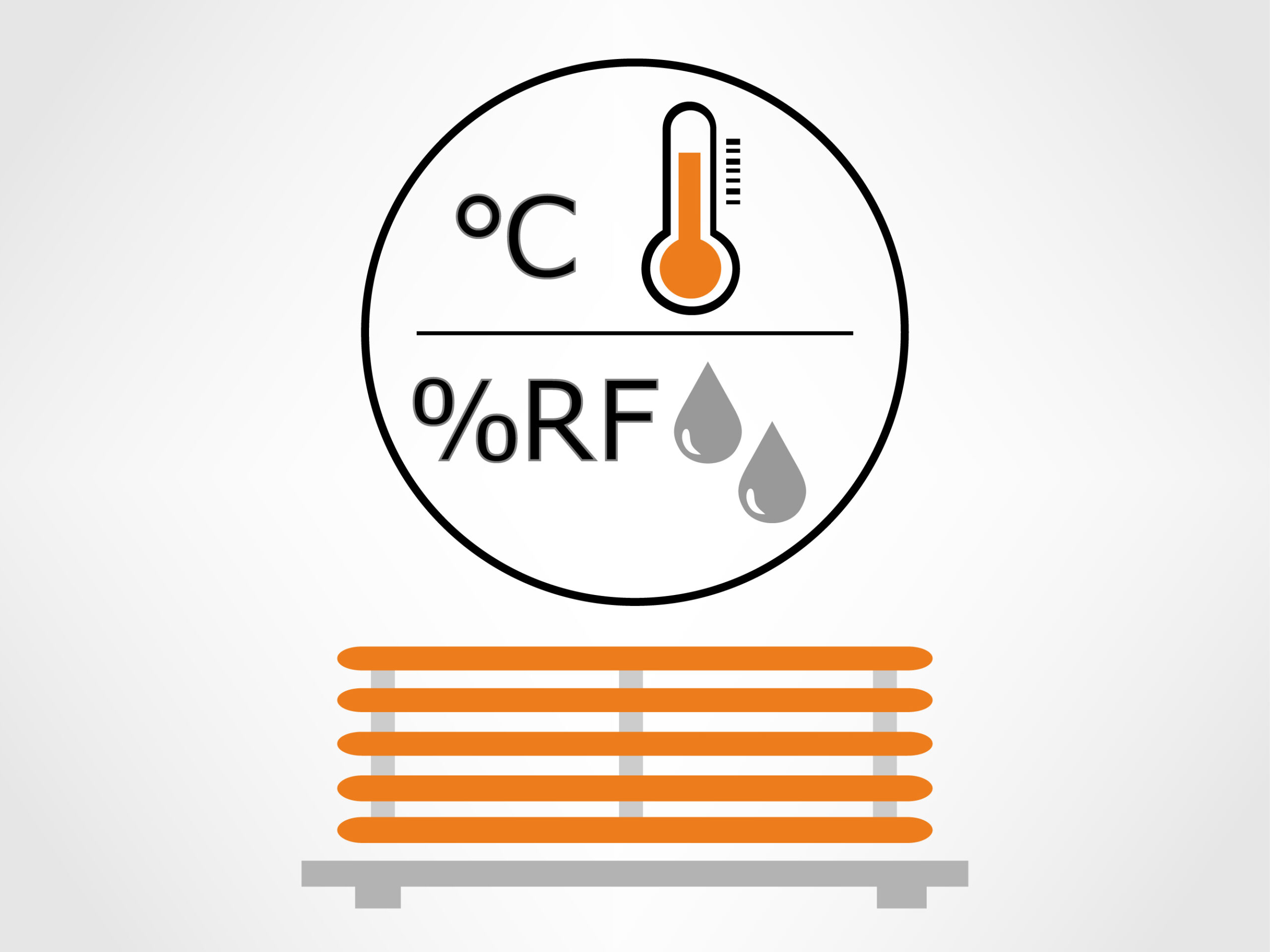

STORAGE/HANDLING OF FIBROTECH WOOD-WOOL CEMENT

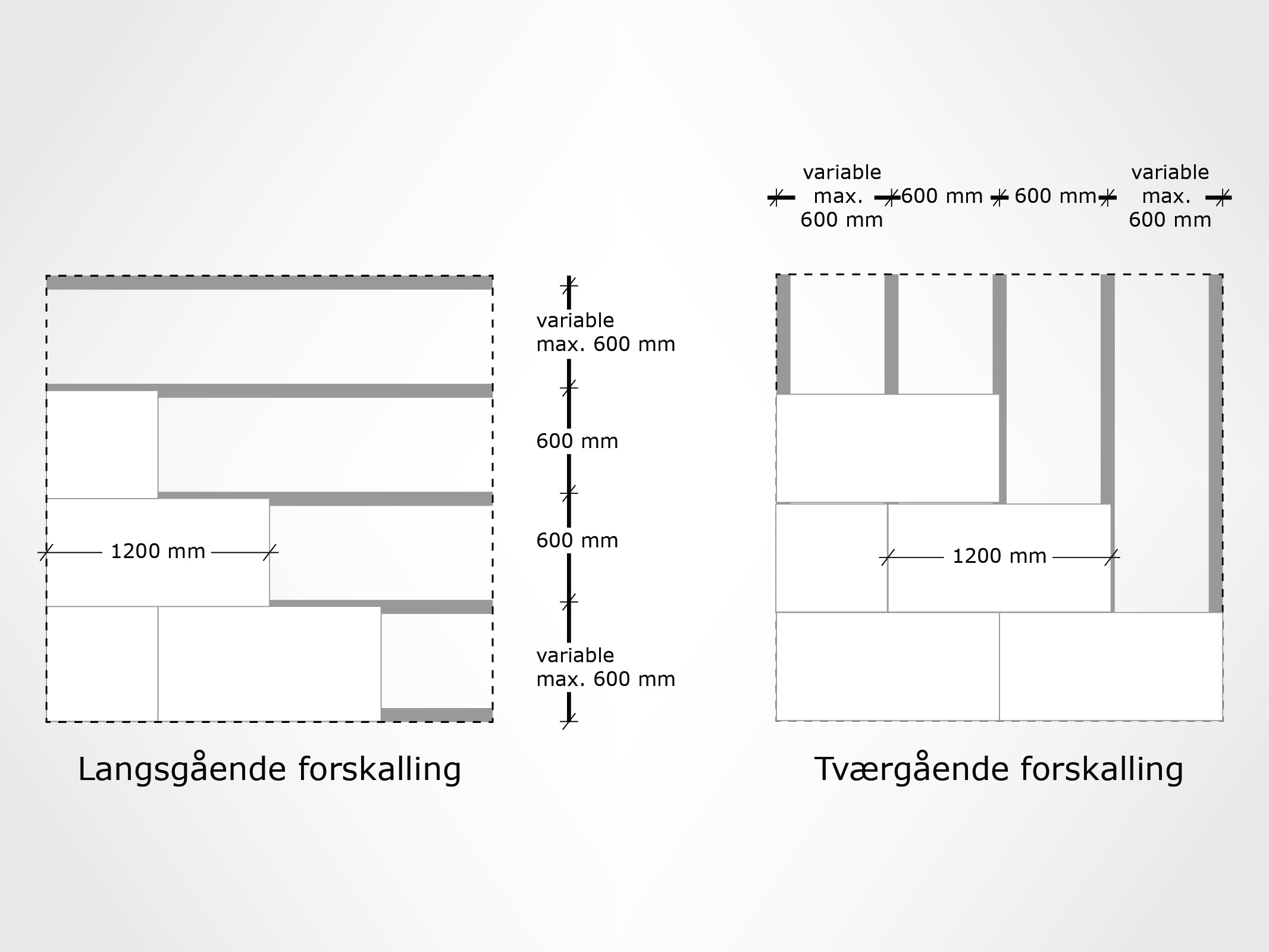

FibroTech wood-wool cement installation

Operation and maintenance

INSTALLATION INSTRUCTIONS